8月 05, 2021

1850

According to data from Korean fab equipment manufacturers and data from global fab equipment manufacturers collected by TheElec, as of July, the delivery time of fab equipment has increased to an average of 14 months.

The extension of the delivery time is due to chip manufacturers' increased spending on fabs, and the long-term shortage of chips worldwide has led to the lengthening of the time for equipment manufacturers to purchase chips.

Last year, the delivery time of fab equipment was between three and six months. The first quarter of this year was extended to 10 months on average. As of July this year, this time has been further extended, with an average of 14 months. According to people familiar with the matter, the delivery time of some fab equipment has been more than two years.

People familiar with the matter said that the delivery time of front-end process equipment is usually short, but the average delivery time is also more than one year. They said that the delivery time of general equipment is at the highest level in history.

TheElec also studied the lead times of the world's top equipment suppliers. As of July, the delivery time of ASML's ArF equipment is 24 months; the i-line equipment is 18 months; the use time of extreme ultraviolet equipment is 18 months. The back-end equipment manufacturer Disco’s equipment delivery period is between 12 and 15 months.

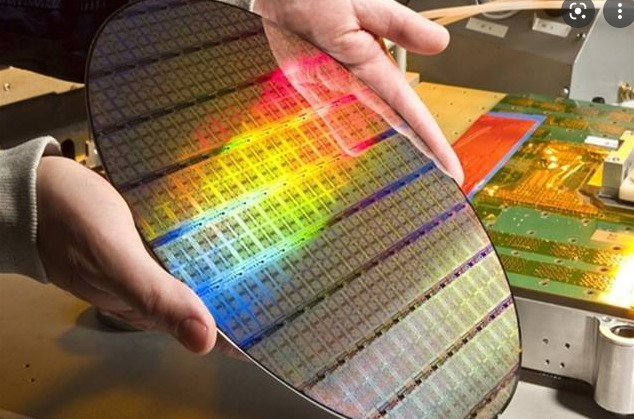

8-inch (200mm) wafer equipment is particularly in short supply. This is because their orders surged due to a shortage of capacity. The current delivery period of KLA's covered equipment is 14 months. The delivery times of Ebara and Applied Materials are 14 months and 13 months, respectively.

The delivery time of equipment manufactured by Tokyo Electron, Hitachi High-Tech, Kokusai Electric, Advantest, Screen Semiconductor Solutions, and Kulicke & Soffa are all around 12 months. Varian Semiconductors and Edwards have been discontinued for approximately 10 months. People familiar with the matter said that the current delivery time of the wire bonding machine supplier of the Chinese company is more than 5 months.

In June, Lam Research Chief Financial Officer Doug Bettinger also stated that the company's equipment delivery time has been delayed.

People familiar with the matter said that some fab equipment manufacturers find it difficult to purchase the field programmable gate arrays (FPGAs) required for manufacturing equipment.

They said that the current shortage of chips has become so severe that it has affected the entire industry chain. They added that the irony is that more fab equipment is needed to make more chips, but there are not enough chips to make fab equipment.

Delays in delivery times have also led to an increase in demand for second-hand fab equipment because of their relatively short delivery times. Most of the used fab equipment uses the core components of the previous equipment and upgrades them to be usable. The demand for 8-inch second-hand equipment is rapidly increasing. According to market research firm VLSI Research, the price of second-hand equipment in the first half of 2021 has risen by an average of 20% over the previous year.

Lam Research said in the second quarter conference call that its refurbished equipment business (called the customer support business group) also achieved a record sales of $1.4 billion in the second quarter.

The high demand and insufficient supply of fab equipment are expected to continue for some time. According to SEMI, fab equipment expenditures in 2021 are expected to increase by 15.5% over the previous year, reaching US$70 billion. The organization stated that this will increase by another 12% year-on-year in 2022, reaching more than US$80 billion.