在Centry,我們渴望成為工程師和買家的首選來源,提供電子設計、原型設計、測試和製造服務。請參閱我們的品質政策、品質手冊和證書。我們對客戶滿意度、訂單精確度和準時交貨的承諾定義了我們卓越的客戶服務。

我們84%的供應商直接來自原始製造商或信譽良好的全球分銷商,而16%的供應商是從經過驗證的正宗OEM或庫存商中精心挑選的。

我們所有的貨物都完全可追溯到其來源和各自的製造商,確保透明度和真實性

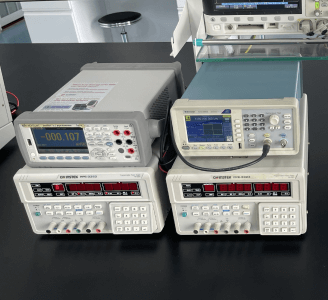

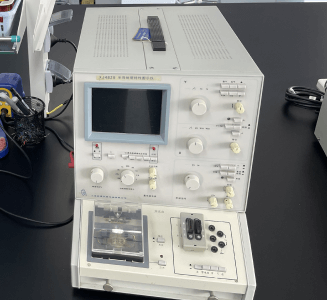

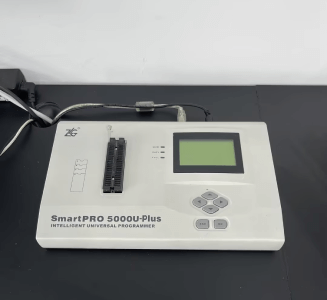

我們的內部實驗室配備了全面的測試儀器,確保嚴格的品質控制措施

我們不斷完善我們的程序以超越客戶的要求,提供滿足所有規格並在整個生命週期中證明可靠性的產品

盛世紀與White Horse Laboratories 和CECC Laboratories合作,恪守全球採購和供應鏈管理承諾。我們的測試、檢驗和包裝部門是為了應對不合格和假冒電子產品的氾濫而建立的。

我們在發貨前提供幾乎所有組件的測試報告和產品品質驗證。我們廣泛的內部實驗室網路已通過第三方認證,可確保進行全面可靠的測試,從而最大限度地降低客戶的風險。

我們提供全面的電子元件檢測服務,對偵測仿冒元件至關重要。大多數部件都經過嚴格測試,以防止任何有缺陷或假冒的產品進入市場。

高解析度顯微鏡:提供高放大倍率、清晰度,並檢查組件的微觀結構、標記和表面細節。能夠觀察表面狀況和微觀結構特徵.

可焊性測試儀:通過檢查元件在創建焊點時的可靠性來評估其焊接能力。確保附著力和可靠性,優化焊接性能和耐久性。

XRF 光譜儀:此設備可偵測材料內的元素成分,分析成分的化學組成,以確認材料的真實性和合規性.

X射線透射設備:本設備使用X射線檢查組件的內部結構,以識別組件內部結構中隱藏的不規則或變化.

關鍵功能測試:測試重要的電子元件參數,如電壓、電流、功率、時序、頻率、相位、雜訊和失真。為工程師提供準確的數據來評估是否符合設計規範.

電性能測試儀:測試電阻、電容、電感、電導率、擊穿電壓、雜訊、失真等電性能參數。為工程師提供精確的數據來評估是否符合設計要求.

雷射開封機:使用雷射光束非破壞性地打開電子元件封裝。便於內部檢查、維護及返工,且不會造成損壞.

程式燒錄設備:使用程式設計電路將程式或資料寫入電子元件記憶體。協助程式設計、燒錄和測試組件。

確保組件外觀完美無缺、無損壞或異常.

確認認證文件的合規性和有效性

驗證組件可追溯到原始製造商.

利用X射線等無損檢測方法檢查內部結構

分析組件內的材料以確保它們符合規格

評估組件的功能性能以滿足標準.

評估不同溫度和濕度下的性能和耐腐蝕性

驗證組件上標籤的準確性和合規性

確保認證文件的完整性並評估包裝條件

深入檢查部件的外觀,並專注於細微缺陷.

通過解封裝和晶片評估來評估晶片完整性。

提供詳細的報告,總結所有測試結果和發現。

01

01

02

02

03

03